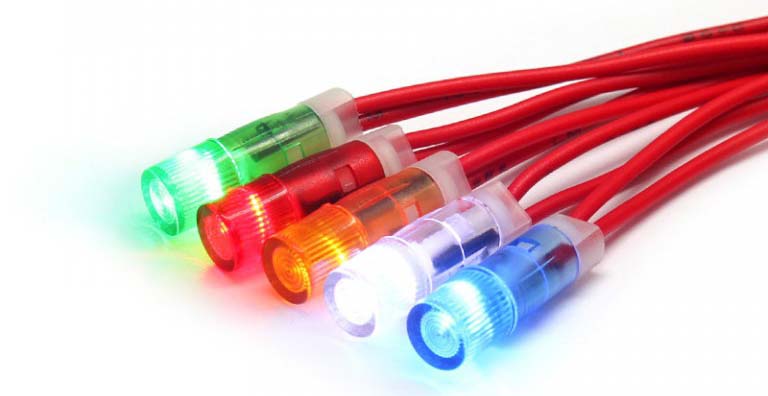

LAMP LED

1. Welding conditions :(the welding spot should be more than 2mm away from the resin root)

Dip welding: please finish the welding once within 5 seconds at 260℃, and avoid the resin immersing in the tin tank.

Soldering iron: use 30W soldering iron, its tip temperature is not higher than 350℃, welding 1 time in 5 seconds.

Do not apply external force to the product during welding. Pay attention to avoid LED pin corrosion or discoloration, otherwise it will cause welding difficulties, it is recommended to use as soon as possible.

2. Usage:

Pin forming must be completed before welding. The distance between the mounting holes on the circuit plate should be the same as that between the electrode pins.

The product in the state of high temperature lead cutting will produce bad, please in the room temperature lead cutting.

Before the welding temperature returns to normal, the LED must not be subjected to any vibration or external forces.

3. Electrostatic protection

High brightness blue, green and white products are sensitive to static electricity, in the use of the need to pay attention to the surge of static electricity will damage or damage the product, and the product contact with the workbench please use conductive pad through the resistance ground; The tip of the soldering iron must be grounded; Ion generators are recommended.

4.Cleaning

Special care must be taken when cleaning colloid with chemicals, as some chemicals damage the colloid surface and cause discoloration such as trichloroethylene, acetone, etc. Ethanol can be used to wipe, impregnate, the time at room temperature does not exceed 3 minutes.

CHIP LED

1. Welding conditions:

Reflow welding: please preheat within 2 minutes at 150℃, and weld once at 240℃ and 5s after heating.

Soldering iron welding: use up to 25W of controllable temperature soldering iron, its tip temperature is not higher than 320℃, in 3 seconds to complete the welding once.

Do not apply external force to the product during welding. Do not bend the line plate after welding is completed.

2. Packaging:

The purpose of moisture-proof packaging is to ensure the lowest moisture content in the packaging bag, as the moisture absorption of the resin causes evaporation and expansion during welding, which may cause interface stripping.

The product should be used within one year from the date of packaging. Before the packaging bag is opened, it should be stored in an environment of temperature 5~30℃ and relative humidity <60%.

After the packaging bag is unsealed, the product must be welded and used within 24 hours; otherwise, the product must be stored in the environment of temperature 5~30℃ and relative humidity <30% for no more than a week. If there are any unused products, please return them to the moisture-proof bag and keep them sealed

If the product exceeds the above storage requirements or is damp, it must be baked at 60±5℃ for 12 hours.

Product electrode surface is gold-plated, prone to corrosion or discoloration resulting in welding difficulties, it is recommended to use as soon as possible.

Be careful to avoid rapid changes in ambient temperature, especially in humid environments.

3. Electrostatic protection

High brightness blue, green and white products are sensitive to static electricity, in the use of the need to pay attention to the surge of static electricity will damage or damage the product, and the product contact with the workbench please use conductive pad through the resistance ground; The tip of the soldering iron must be grounded; Ion generators are recommended.

Tel: +86-021-33555507

Email: [email protected]

Add: No.655 Jiujing Road, Songjiang District Shanghai, China, 201615